|

The course is approved by the DNV and meets the requirements laid down in

Regulation I/12, Sections A-I/12, B-I/12 and Table A-V/1-2-1, A-V/1-2-2 of the

STCW Convention and Code as amended in 2010 and is in compliance with

SIGTTO LNG Shipping suggested competency standards.

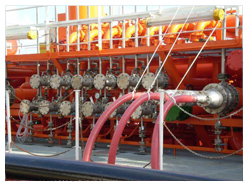

The LNG simulator is modelled on the Moss Rosenberg design 132,000 cum

LNG carrier having 4 cargo tanks. The cargo control system consist of 2HD and

2LD compressors, LD and HD heaters, vaporisers and forcing vaporiser, 2 deep

well cargo pumps of 1500 cum/hr and spray pumps 50 cum/hr. Boil off gases

can be sent to steam boiler. Tank valves can be operated/ controlled from CCR

and at the tank dome on the deck panel. Additionally there are temperature,

pressure and level gauges, fixed gas detection system, IGG plant and ESD.

|

|

Physics and Chemistry

Principles of Design

Regulations and Guidance, Principles of Tank Atmospheres,

Properties of Material, Hazards from LNG and Relevant Gases

Environmental Impacts, Risk assessment, Responsibilities, Contingency plans,

Review of Off-line exercises. Record Keeping and Planning/ Cargo containment systems,

Cargo Equipment - Air and IG driers, IG, N2, LNG Vapourizers, HD

LD compressors, Heaters, Forcing vapourizers, Pumps,

Cargo Support systems, GCU, Re-gasification plant, Cargo spaces, Cofferdam heating, Gas detection system (Fixed)

Warming up, Gas Freeing, Aeration, connections, Gassing up, Cooling Down, Loaded and Ballast passage, Discharging, Heel/Ballast/ Loading

ESD, Emergency mooring systems, Water curtain, Drenching system (Water spray system)

DCP system, Level Gauging system, Custody Transfer system

Certified Safe Electrical equipment, HV systems, IAS systems, Gas combustion systems

Non-standard and emergency operations

|